Revolutionizing the Future: AK Industries’ Pioneering Manufacturing Techniques

The Initiatives Spurring Evolution in Manufacturing

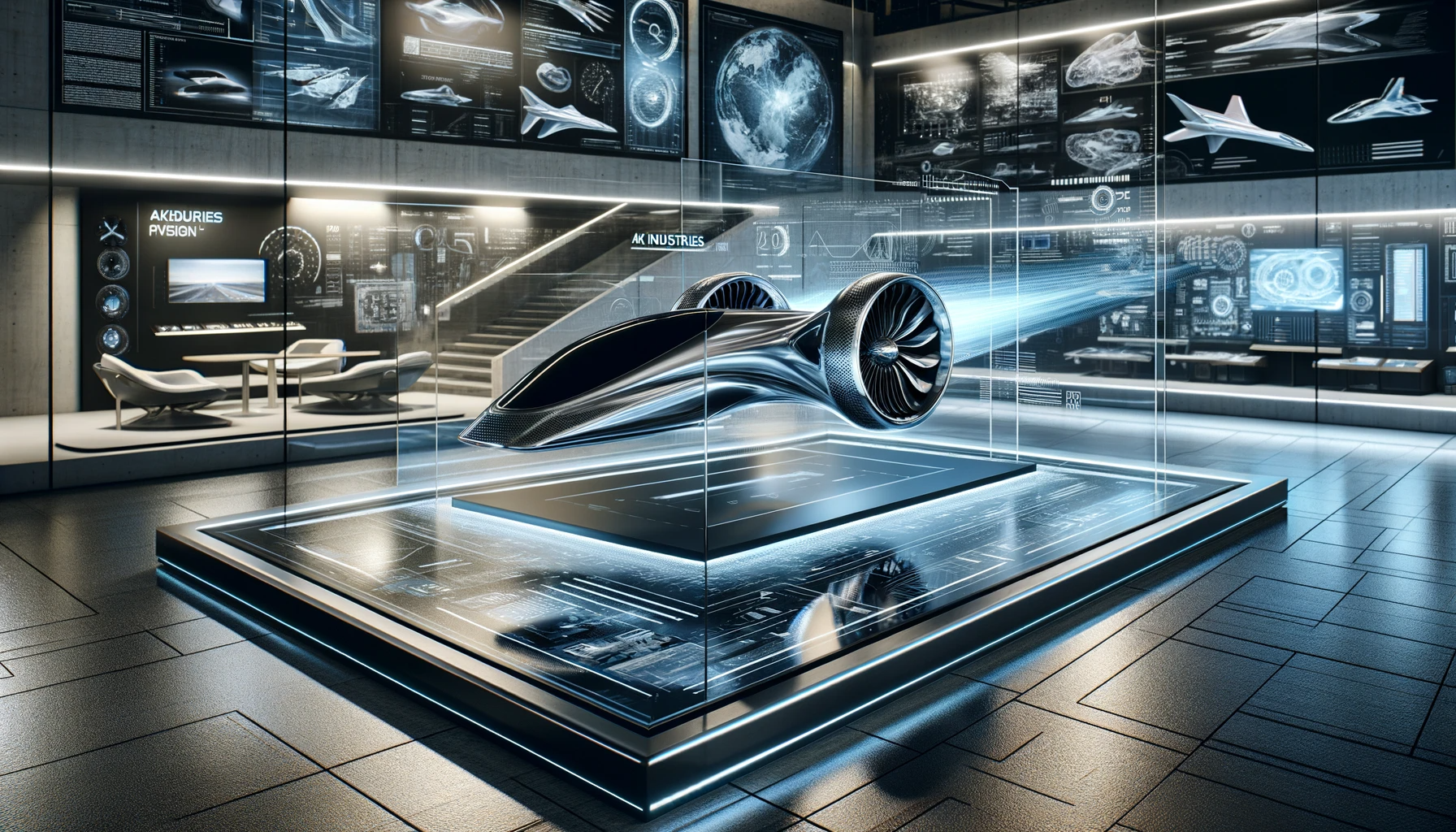

Revolutionizing the Future: AK Industries‘ Pioneering Manufacturing Techniques have been instrumental in spurring evolution in the manufacturing industry. With a focus on innovation, AK Industries has leveraged technology and automation to optimize manufacturing processes and enhance efficiency, quality, and safety in production. By integrating robotics and AI, AK Industries has revolutionized traditional manufacturing, enabling human-machine collaborations that enhance productivity and enable new levels of precision. Through their pioneering use of additive manufacturing techniques, AK Industries has positioned themselves as a leader in the industry, targeting and controlling premium market segments. With their expertise and emphasis on creativity and innovation, AK Industries is playing a pivotal role in driving the evolution of manufacturing technology. #aktoolanddie #northamerica #usa

Embracing Change: Reimagining Traditional Manufacturing

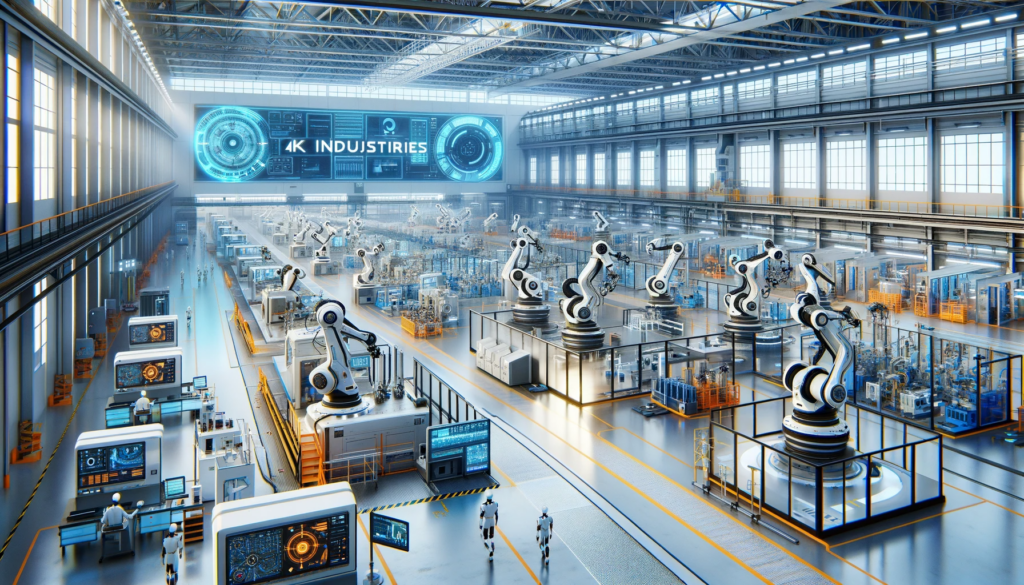

With the rapid advancements in technology and the ever-growing demands of the market, traditional manufacturing processes are undergoing a significant transformation. AK Industries, through its pioneering manufacturing techniques, is revolutionizing the future of manufacturing. By embracing change and adopting automation and AI, AK Industries has been able to optimize its supply chain, improve consistency, and stay ahead of industry trends. The implementation of robotics and other cutting-edge technologies has allowed the company to streamline its production processes, increase speed and accuracy, and enhance product quality. AK Industries’ innovative approach to manufacturing has not only reduced labor costs but has also positioned the company at the forefront of the industry, giving them a competitive edge in the market.

Automation and AI have played a pivotal role in reshaping traditional manufacturing practices. AK Industries recognizes the importance of integrating robotics into its production operations. With the use of advanced robotics technologies such as AGVs and mobile robots, the company has experienced improved performance, increased productivity, and enhanced quality control. The integration of vision systems, artificial intelligence applications, and other state-of-the-art technologies has minimized human error and eliminated bottlenecks in production cycles. These automation opportunities have led to significant cost reduction, waste reduction, and improved quality checks, ensuring that the final products meet the highest standards. By leveraging robotics and embracing change, AK Industries is setting new benchmarks in manufacturing and paving the way for the future of the industry.

Futurethinking Initiatives: Steps Towards a New Age

Revolutionizing the Future: AK Industries’ Pioneering Manufacturing Techniques have had a profound effect on the industry. With the introduction of automation and AI, AK Industries has been able to create a more efficient and streamlined manufacturing process. By incorporating advanced technology and embracing new approaches, conflicts within the manufacturing industry have been minimized. The use of robotics in various processes has allowed AK Industries to target and control premium market segments, ensuring their position as a leader in the industry. With their pioneering additive manufacturing techniques, AK Industries is shaping the future of manufacturing and setting new standards for the industry.

As AK Industries continues to explore new technologies and manufacturing methods, the integration of robotics has become a key focus. Robotics has had a transformative impact on traditional production, revolutionizing the way products are manufactured. The use of robots in manufacturing processes has increased precision and efficiency, resulting in higher quality products. AK Industries has embraced this technology, adopting advanced robotics systems to optimize their manufacturing processes. By leveraging the capabilities of robotics, AK Industries is able to achieve greater speed, accuracy, and flexibility, ensuring they stay ahead in an increasingly competitive market. The intersection of manufacturing and robotics is paving the way for a new era in the industry, where innovation and automation go hand in hand.

The Intersection of Manufacturing and Robotics

The intersection of manufacturing and robotics has revolutionized the future of AK Industries’ pioneering manufacturing techniques. With the use of automation and AI, AK Industries has been able to streamline their manufacturing processes and incorporate additive manufacturing techniques. This has allowed the company to target and control premium market segments, giving them a competitive edge in the industry. The integration of robotics in manufacturing has not only increased efficiency and productivity but has also opened up new possibilities for technology-driven advancements in the manufacturing sector. AK Industries’ innovative approach to incorporating robotics in their manufacturing processes is a testament to the transformative impact it can have on traditional production methods.

The Pivotal Role of Robotics in Manufacturing

The pivotal role of robotics in manufacturing cannot be overstated. With the use of automation and AI, robotics has revolutionized the future of manufacturing. AK Industries, a pioneering company in the industry, has embraced robotics and advanced additive manufacturing techniques to target and control premium market segments. These innovative processes have not only increased efficiency and precision in manufacturing, but also opened up new possibilities in product design and development. Robotics has become an essential tool in the manufacturing industry, allowing companies like AK Industries to stay at the forefront of technology and meet the ever-changing demands of the market.

The Transformative Impact of Robotics on Traditional Production

The transformative impact of robotics on traditional production is evident in the revolutionizing future envisioned by AK Industries’ pioneering manufacturing techniques. Through the use of automation and AI, AK Industries has successfully embraced the power of robotics to optimize manufacturing processes. This has resulted in increased efficiency, improved productivity, and enhanced quality control. By integrating robotics into their manufacturing operations, AK Industries has positioned themselves as leaders in the industry, showcasing the immense potential of robotics in shaping the future of manufacturing.

The introduction of robotics has not been without its challenges. Implementing robotics in traditional production methods has presented complexities and uncertainties. Issues such as voltage stability, power assistance, and machine failures have required careful consideration and strategic planning. However, AK Industries’ commitment to innovation and continuous improvement has allowed them to overcome these obstacles and unlock the full potential of robotics in their manufacturing environment. By leveraging additive manufacturing techniques and pushing the boundaries of technology, AK Industries has set a new standard for the industry, paving the way for a future where robotics play a central role in manufacturing processes.

Charting the Course: AK Industries’ Role in Revolutionizing the Future

AK Industries has emerged as a trailblazer in revolutionizing the future of manufacturing through their pioneering techniques and innovative use of automation and AI. By embracing advanced manufacturing technologies and implementing state-of-the-art robotics systems, AK Industries has successfully transformed traditional manufacturing processes. Their expertise in additive manufacturing techniques has allowed them to stay at the forefront of the industry, enabling efficient and cost-effective production. With a focus on quality and precision, AK Industries has positioned itself as a leader in the market, targeting premium market segments and delivering cutting-edge solutions. Through their continuous research activities and industry leadership, AK Industries sets a roadmap for the future of manufacturing, driving advancements and pushing the boundaries of what is possible in the industry.

Conclusion

AK Industries has truly revolutionized the future of manufacturing with their pioneering techniques. By embracing automation and artificial intelligence, they have transformed the traditional manufacturing processes. The use of robotics has played a pivotal role in this transformation, allowing for greater efficiency, precision, and customization in production. AK Industries has also embraced additive manufacturing techniques, which have opened up new possibilities in terms of design alternatives and resource maximization. These advancements in technology have positioned AK Industries as a leader in the industry, enabling them to target and control premium market segments. Their commitment to innovation and staying at the forefront of technology has truly revolutionized the future of manufacturing.

FAQ

What are some of the initiatives that are driving the evolution in manufacturing?

Some of the initiatives driving the evolution in manufacturing include embracing new technologies, implementing automation and robotics, and reimagining traditional manufacturing processes.

How is AK Industries embracing change and reimagining traditional manufacturing techniques?

AK Industries is embracing change by adopting new technologies and innovative manufacturing techniques. They are reimagining traditional manufacturing by integrating automation and robotics into their production processes.

What are some future-thinking initiatives that AK Industries has taken?

AK Industries has taken future-thinking initiatives such as investing in advanced manufacturing technologies, leveraging data analytics for process optimization, and implementing sustainable practices in their operations.

How does the intersection of manufacturing and robotics impact the industry?

The intersection of manufacturing and robotics revolutionizes the industry by increasing efficiency, precision, and productivity. It allows for more complex tasks to be automated, freeing up human workers to focus on higher-value activities.

What is the pivotal role of robotics in manufacturing?

Robotics plays a pivotal role in manufacturing by automating repetitive tasks, improving accuracy and consistency, increasing production speed, and enhancing overall operational efficiency.

How does robotics transform traditional production methods?

Robotics transforms traditional production methods by reducing human error, minimizing downtime, enabling flexible manufacturing, and enhancing overall quality control. It allows for faster and more efficient production processes.

What is AK Industries’ role in revolutionizing the future of manufacturing?

AK Industries plays a significant role in revolutionizing the future of manufacturing through their pioneering manufacturing techniques, adoption of advanced technologies, and commitment to innovation. They are at the forefront of driving change in the industry.

Can you summarize the main points discussed in this article?

This article explores how AK Industries is revolutionizing the future of manufacturing through their pioneering techniques. It discusses the initiatives that are driving the evolution in the industry, the intersection of manufacturing and robotics, and the transformative impact of robotics on traditional production. It also highlights AK Industries’ role in charting the course towards a new age of manufacturing.